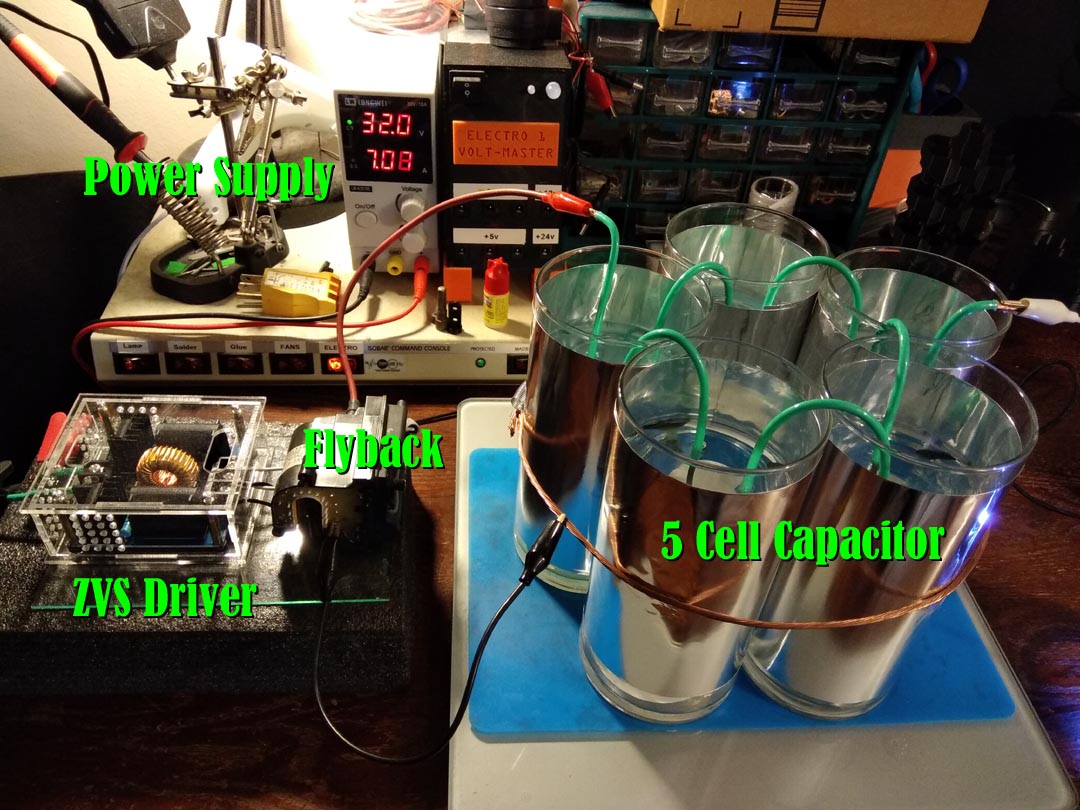

WCSG "Original Prototype"

Online Instruction Manual

HARDWARE REQUIRED

The hardware required to run a small-scale WCSG is:

ZVS driver / 30v, 10A

A variable power supply capable of 30 volts, 10 amps

High-voltage / high amperage capacitors (recommended 5-8 cell saltwater capacitors)

18 to 16 gauge wires for efficiently moving high current throughout the system

AIR INPUT SPECIFICATIONS

Air hose outer diameter - 1/2" or 20mm pipe

Airflow - '6 cmm' may be supplied for best performance (an old medical BiPAP works well to regulate airflow)

SAFETY

Never look directly at the spark gap without the proper use of eye protection - use an arc welder's mask or goggles of at least SHADE 9. Sunglasses just won't do.

ALWAYS disconnect, ground out or discharge your capacitors before making adjustments to the electrodes or working on the system. *Salt water capacitors need to be kept grounded for at least 3 full seconds to dissipate all of their charge!

Ozone: As with any high-voltage application, spark gaps emit dangerous levels of ozone that must be adequately ventilated at all times. Be sure to always have fresh air moving through your workspace.

OPERATION

Adjust and check both electrode alignments before starting the system. Do not touch the electrodes without first turning off power and disconnecting your capacitors.

A distinctive tone or 'banshee scream' will be heard when the system is pulling water up the electrode walls properly. With practice, you will become very familiar with this sound.

SETUP / ADJUSTMENT

All components should be aligned relatively center with the outer electrodes.

The upper PFR positive can be adjusted away or towards the GFE negative (depending on user input voltage) and should always point at a 30 degree angle to the GFE negative's tip.

The GFE negative should also protrude from the water 1 cm or less, depending on input voltage - if the water level is too low (or too much voltage is applied), the electrode will dry out and ignite. If the water level is too high, your WCSG will 'gurgle', splash or make contact with the water.

TROUBLESHOOTING / TIPS

No spark - increase your voltage or shorten the distance between the spark gap.

Tip: If the electrode ends have rounded from heat (over-voltage) or contain excess corrosion, simply trim the ends or clean the electrodes.

Have spark / turn system off / no spark - If the spark fails to re-initiate without changes to the system, this can be caused by the GFE electrode becoming too wet (pitting and corrosion on the surface can lead to higher water retention).

Tip: Turn up the voltage higher at start and then re-adjust to the previous stable voltage level.

Electrodes catching on fire - This can be caused by either not enough capacitance, too much voltage, a low water level, or your electrodes are too close together.

Tip: If your spark gap color is a 'dark purple' and not 'bright blue', you either do not have enough capacitance and need to increase the number of capacitors (or change your capacitor type), or there is too little water being drawn up the electrode walls.